CATEGORY

China Coils High Carbon Steel Galvanized Spring Wire

Galvanized high carbon steel spring wire offers a combination of strength, durability, and corrosion resistance, making it a valuable material for applications that require reliable and long-lasting springs.Sunshine is one of the best galvanized steel wire suppliers in China.

Category:

Products

IRON WIRE SERIES

Galvanized Wire

China Coils High Carbon Steel Galvanized Spring Wire

China Coils High Carbon Steel Galvanized Spring Wire

Steel Galvanized Spring Wire Introduction

Galvanized steel spring wire is a type of high carbon steel wire that has been coated with a layer of zinc to protect it from corrosion. The process of galvanization involves immersing the steel wire in a bath of molten zinc, which forms a protective coating on the surface. This coating provides excellent corrosion resistance, making galvanized steel spring wire suitable for various applications.

Galvanzied Steel Spring Wire Properties

| Galvanzied Steel Spring Wire Brand | SUNSHINE |

|---|---|

| Material | high carbon steel 60# 70# 75# 72A 72B 82B |

| Diameter | 0.5mm-12mm |

| Standard | GB/T4357,EN10270,DIN17223 or other as required |

| Coatings | Galvanized coatings and black steel wires |

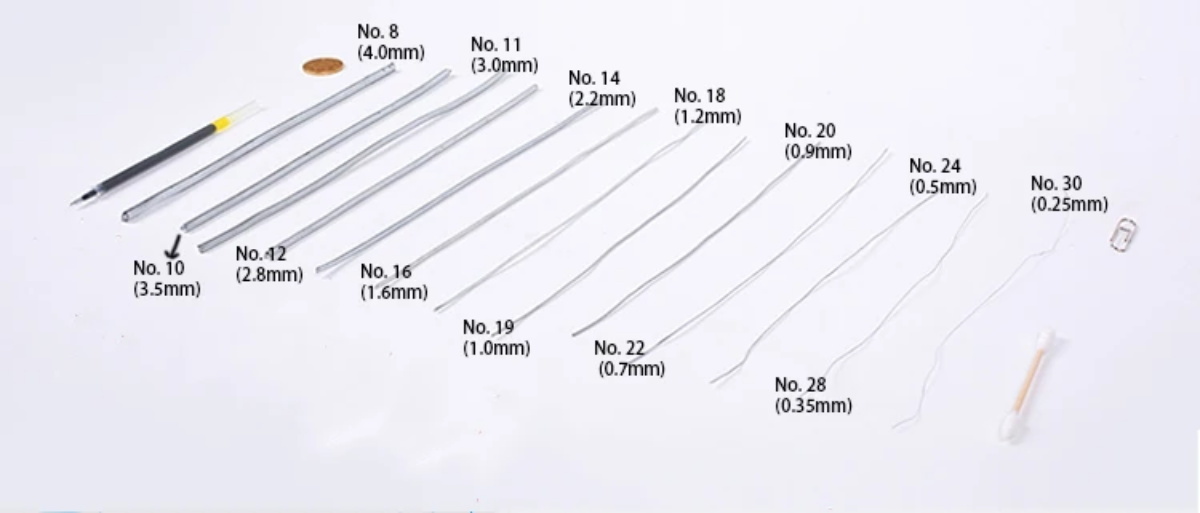

Galvanzied Steel Spring Wire Gauge

|

Wire Gauge |

SWG(mm) |

BWG(mm) |

Metric(mm) |

|

8 |

4.05 |

4.19 |

4.00 |

|

9 |

3.66 |

3.76 |

4.00 |

|

10 |

3.25 |

3.40 |

3.50 |

|

11 |

2.95 |

3.05 |

3.00 |

|

12 |

2.64 |

2.77 |

2.80 |

|

13 |

2.34 |

2.41 |

2.50 |

|

14 |

2.03 |

2.11 |

2.50 |

|

15 |

1.83 |

1.83 |

1.80 |

|

16 |

1.63 |

1.65 |

1.65 |

|

17 |

1.42 |

1.47 |

1.40 |

|

18 |

1.22 |

1.25 |

1.20 |

|

19 |

1.02 |

1.07 |

1.00 |

|

20 |

0.91 |

0.84 |

0.90 |

|

21 |

0.81 |

0.81 |

0.80 |

|

22 |

0.71 |

0.71 |

0.70 |

Galvanzied Steel Spring Wire Manufacturing Process

-Wire Drawing: The process begins with wire drawing, where steel rods or billets are drawn through a series of dies to reduce their diameter and form the desired wire size. This step helps in improving the wire's tensile strength and surface finish.

-Cleaning: The drawn wire is then cleaned to remove any impurities, such as dirt, oil, or rust, that may be present on the surface. This is typically done through a cleaning process involving chemical treatments or mechanical cleaning methods.

-Galvanization: The cleaned wire is then coated with a layer of zinc through a process called galvanization. There are two common methods for galvanizing steel wire: hot-dip galvanizing and electro-galvanizing.

-Hot-Dip Galvanizing: In this method, the wire is immersed in a bath of molten zinc, ensuring complete coverage of the wire's surface. The wire is then withdrawn from the bath and allowed to cool, forming a thick layer of zinc coating.

-Electro-Galvanizing: In this method, the wire is passed through an electrolyte solution containing zinc ions. An electric current is applied, causing the zinc ions to bond with the wire's surface, forming a thin layer of zinc coating.

-Cooling and Drying: After the galvanization process, the wire is cooled and dried to ensure the zinc coating adheres properly to the wire's surface.

-Inspection and Testing: The galvanized steel spring wire undergoes rigorous inspection and testing to ensure it meets the required specifications and quality standards. This may include checking the wire's diameter, tensile strength, and adherence to the zinc coating.

Galvanized High Carbon Steel Spring Wire Feature

-Strength and Durability: High carbon steel is known for its excellent strength and durability. When used in spring wire applications, it provides the necessary resilience and resistance to deformation. This makes galvanized high carbon steel spring wire suitable for demanding applications that require strong and durable springs.

-Corrosion Resistance: The galvanization process adds a layer of zinc coating to the high carbon steel wire, providing enhanced corrosion resistance. The zinc coating acts as a sacrificial layer, protecting the underlying steel from rust and corrosion caused by exposure to moisture, chemicals, and other environmental factors. This corrosion resistance ensures the longevity and reliability of galvanized high carbon steel spring wire, even in harsh conditions.

-Versatility: Galvanized high carbon steel spring wire can be used in a wide range of applications across various industries. Its strength, durability, and corrosion resistance make it suitable for automotive manufacturing, construction, industrial machinery, and other sectors where robust and reliable springs are required.

Galvanized Steel Wire Applications

-Wire Rope: Galvanized steel wire is commonly used in the production of wire ropes. It provides strength, durability, and corrosion resistance, making it suitable for applications such as lifting, rigging, and securing loads. Wire ropes find applications in industries like construction, shipping, and mining.

-Conveyor Belts: Galvanized steel wire may be used in the manufacturing of conveyor belts. The wire provides strength and stability to the belt, allowing it to transport materials efficiently. Conveyor belts are used in industries such as manufacturing, mining, and logistics.

-Mesh and Fencing: Galvanized steel wire is utilized in the production of wire mesh and fencing. The wire is woven or welded to create mesh panels or fencing structures that provide security, containment, and reinforcement. These applications are commonly seen in construction sites, agriculture, and residential areas.

-Instrumentation and Control: Galvanized steel wire may be used in the manufacturing of cables and wires for instrumentation and control systems. The galvanized coating provides corrosion resistance, ensuring reliable performance in harsh environments.

-Fasteners and Ties: Galvanized steel wire is commonly used in the production of fasteners, ties, and clips. These include wire ties, wire ropes, and wire fasteners used in construction, packaging, and other industries.

Galvanized steel wire is used in the production of springs for various applications. Galvanized Steel Spring Wire can provide mattress spring,mechanical spring and other usages. It provides the necessary strength and resilience required for springs used in automotive, industrial, and household products.

Packing

coil wrapped

China Galvanzied Steel Spring Wire for sale

galvanized spring wire where to buy?

SUNSHINE has own professional team and equipment to inspect product items such as material standard, wire size, weight,tensile strength, and other customer demand. Meanwhile, we could guaranteed the products quality as you expect.

Whether you have specific requirements or need assistance in selecting the right products, our dedicated team is here to help. Contact us today and let SUNSHINE be your trusted partner for all your hardware and construction material needs.

FAQ

1. who are we?

We are based in Hebei, China, start from 2010,sell to South America(50.00%),Mid East(20.00%),Africa(15.00%),North America(10.00%),Eastern Europe(5.00%). There are total about 11-50 people in our office.

2.how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

Nails,Steel Wire,Wire Pipe,Wire Mesh,Malleable Iron Fitting

4. why should you buy from us not from other suppliers?

The products are mainly exported to Africa, European and American markets and South America; the company has its own stable cooperative factory, the product quality is first-class in the country, and has a good reputation in the international market.

5. what services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF;

Accepted Payment Currency:USD,EUR,CNY;

PREV

China Farming Oval Galvanized High Carbon Steel Wire Exporter

PRODUCT MESSAGE